UV has a strong influence on the durability of materials. 20+ year old A1 project in South Africa shows that (coated) A1 will withstand (severe) UV influence.

When an uncoated A1 object is exposed to (intensive) UV the very thin top layer of the A1 object will be affected (erosion) within a few months. This will mainly be noticeable by a change of the colour of the A1 object. After this initial period the erosion by UV will continue but at a very slow rate.

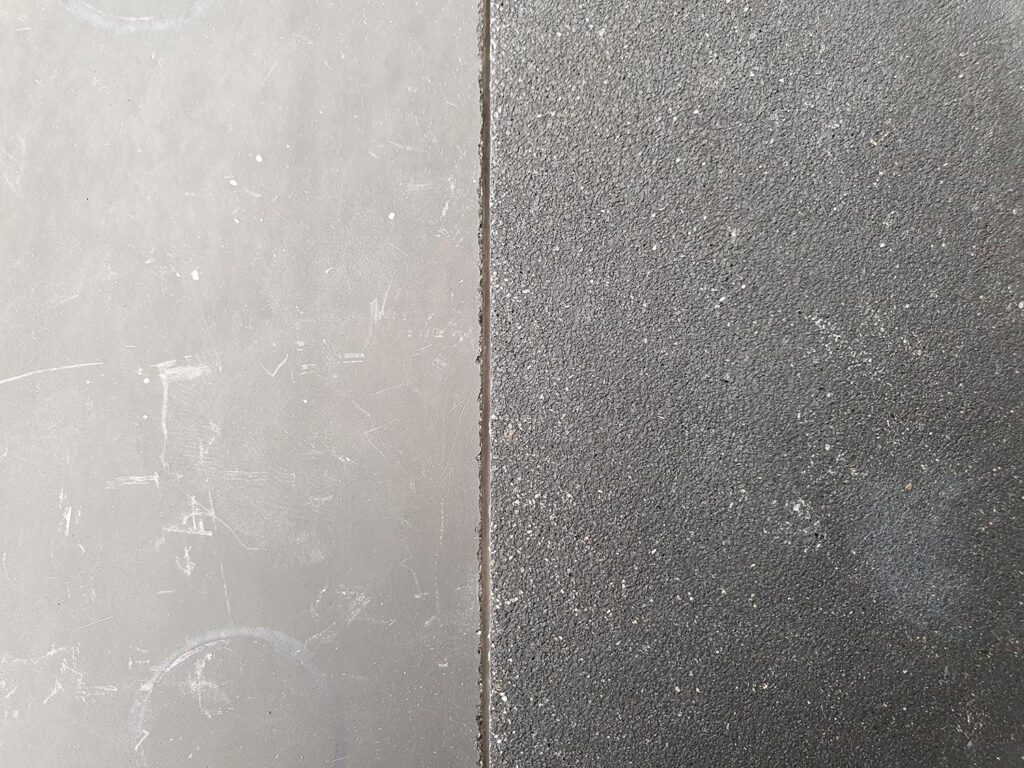

A1 glass fibre reinforced panel without a sealer/coating system. On the left directly after de-moulding. On the right after five years of exposure to sun light and rain – The Netherlands.

Adding sand to the A1 object (1 part A1 Liquid, 2 parts A1 Powder and 2 parts Quartz sand) will still result in an initial erosion of a very thin top layer but after this the added sand will almost stop the erosion process of the A1 object caused by UV.

A1 glass fibre reinforced panel with SAND added but without a sealer/coating system. On the left directly after de-moulding. On the right after five years of exposure to sun light and rain – The Netherlands.

For the best protection we advise applying layers of A1 Sealer PLUS to the A1 object as this layer will act as a barrier between the UV radiation and the A1. As the A1 Sealer PLUS will now be affected by the UV we advise to apply a new layers of A1 Sealer every 6 years. Other coating systems can be used as well if they are damp open (KEIM Soldalan) or the A1 object can release its moist at the backside of the A1 objects (for ventilated Cladding systems).

Similar to many other materials, A1 will attract moist/water at a humidity rate above 90%.

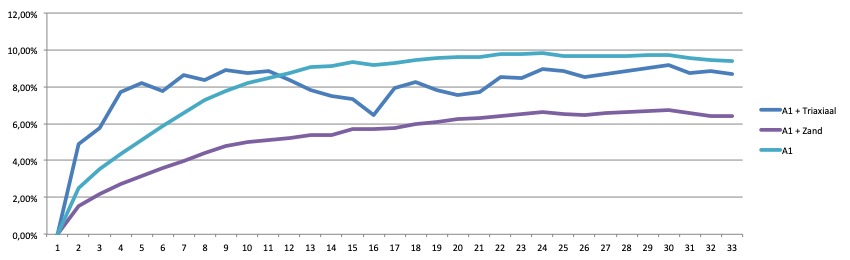

As can been seen in the graph it will take several weeks at very high humidity level to reach the maximum levels of 10 to 11% water absorption. If we add sand to the A1 (1 part A1 Liquid, 2 parts A1 Powder and 2 parts Quartz Sand) the water absorption is significantly lower.

Weight increase in % to totale weight /

number of weeks specimens placed in high humidity environment

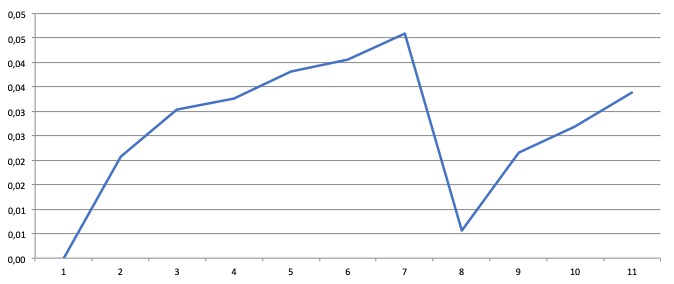

An A1 object will release its water when placed in an environment with a lower humidity (below 70%) at a high speed as can be seen in the graph. It only takes a few days to reach the levels at starting point.

Weight increase in % to totale weight / number of weeks specimens placed in high humidity environment

We have also tested A1 objects fully submerge under water and tested the quality of the top layer with the use of a Shore measurement (picture 1 and 2). Based on these tests an A1 object can be fully submerged under water for a period of 2 months without weakening the top layer. After this period the top layer weakens and the A1 will slowly dissolves in the water. Please be ware that this is a controlled test environment. We strongly advice to make sure your A1 Cladding panels are not placed in an environment where they are submerged under water.

Avoid horizontal parts

A1 can withstand rain showers or an environment with a higher moisture load. In a situation where the A1 object is (very) long exposed to moisture, without the chance to dry again regularly, the top layer can become softer and in extreme cases even loosen from the underlying layers. That is why our advice is to ensure that (rain)water can always drain off the A1 object easily. Provide sufficient slope and avoid horizontal or badly sloping parts in the A1 object.

Avoid places where moisture is collected.

Very occasionally we come across A1 projects where the water can collect in. As long as this place is provided with sufficient protection, it will not be a problem for the A1 for a few days. For a longer period of time, this is something we really do not recommend.

Similar to what we sometimes find on construction sites where A1 panels are stored before being mounted with the panels facing outwards with the wrong side up. This gives the rainwater every chance to collect and, because often no coating is applied to the rear, the water has every chance to penetrate into the A1. Constructively, this is not a problem for the A1 over a short period, but on the visible side, the places where the moisture has penetrated will soon be visible, even after it has dried.

Use filling materials that do not absorb moisture.

A1 is excellent to use in combination with a large number of filling materials. It adheres excellently to, for example, wood, textiles and chicken wire. Is it possible to add almost all small ground materials to the A1 mixtures, creating special shapes in appearance and structure.

For A1 objects that are placed outside, carefully consider beforehand whether this combination of materials also works well here. For example, we know that wood attracts moisture via the A1 and can even expand, causing the A1 layer to crack. Chicken wire will start to rust due to the moisture present in the A1 and this creates traces of rust in the A1. We encountered A1 objects where hydro grains were mixed in the A1 because it gave a nice structure. Subsequently, these hydro grains absorbed so much moisture that the surrounding A1 became soft and the top layer A1 with hydro grains subsequently separated from the underlying glass fabric reinforced A1 layers.

Only use filling materials that do not absorb moisture or that will corrode due to the moisture present. We have had good experiences with materials that do not absorb moisture and rust, such as granite, sand, EPS (styrofoam) and aluminum.

Reinforcement materials and inserts required for mounting can cause problems in outdoor situations when these materials absorb moisture such as wood. Then use aluminum, stainless steel, EPS or pre-produced reinforcement profiles or backs of A1.

A1 needs to breathe.

A1 attracts moisture and also releases it during dry periods. Therefore, the urgent advice not to disrupt this process by using a non-damp open sealing paint or coating. The moisture still present in the A1 is converted into water vapor during warm periods and this can damage the coating system or the A1. In particular A1 objects that are also closed on the inside by, for example, by EPS or another type of foam, show this problem after a number of years.

Be careful with applying to many thick layers of our A1 Sealer PLUS over the A1 panel. Also do not apply one or more layers of A1 sealer PLUS after you have used a (damp open) paint system as this will result in a coating system that has lost its damp open properties.

Make sure residual moisture has disappeared

During the production process, moisture in the A1 liquid reacts with the A1 powder. A part of the moisture remains behind (residual moisture). Therefore, before an object is placed outside, it is important to make sure that the residual moisture has disappeared from the product. The duration of this depends, among other things, on the construction of the A1 object, the thickness of the laminate, the humidity present and the temperature of the storage location. Our advice is to give the A1 object the chance to evaporate the residual moisture in a covered area with room temperature for at least 7 days. At that time, the coating can also be applied.