A1 has excellent fire resistance properties and can be used for projects with high fire resistance requirements.

A1 reinforced with Triaxial Fabric scores a B-s1,d0 classification which increases to even a A2-s1,d0 level after adding 35% of sand to the A1. This is comparable to the classification of bricks and concrete and make A1 suitable in (almost) all situations..

Find below an overview of all the A1 fire tests done, including ASTM E84-15b and fire tests for Marine applications.

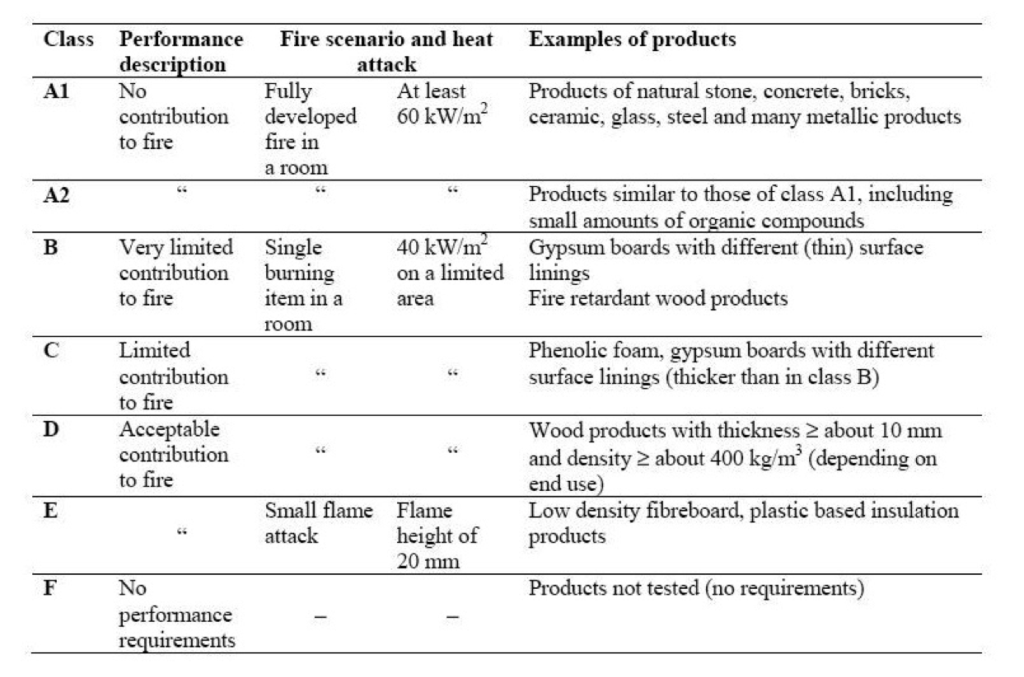

Classification of reaction to fire performance in accordance with EN 13501-1:2002

A1 (Acrylic One) LP01 and A1 Triaxial Fabric: B-s1,d0

Its reaction to fire behaviour is classified: B

The classification to smoke production is: s1

The classification to flaming droplets / particles is: d0

Adding a minimum of 35% of sand to the A1 mixture not only gives a different expression but also improves the fire rating.

Classification of reaction to fire performance in accordance with EN 13501-1:2007+A1:2009:

A1 LP01 and A1 Triaxial Fabric + sand (25% of mass A1): A2 – s1,d0

Classification of reaction to fire performance in accordance with EN 13501-1: 2002

B-s1,d0

Product name:

A1 LP01 and A1 Triaxial

ENGLISH VERSION

Classification of reaction to fire performance in accordance with EN 13501-1: 2002

B-s1,d0

Product name:

A1 LP01 and A1 Triaxial

FRENCH VERSION

Classification of reaction to fire performance in accordance with EN 13501-12007+A1:2009

A2-s1,d0

Product name:

A1 LP01, A1 Triaxial

+ 35% sand

ENGLISH VERSION

Classification of reaction to fire performance in accordance with EN 13501-12007+A1:2009

A2-s2,d0

Product name:

A1 LP01, A1 Triaxial

+ 35% sand

CHINESE VERSION

Evaluation of the surface burning characteristics of a material indentified as A1 in accordance with ASTM E84-15b, standard test method for surface burning characteristics of building materials.

We have performed indicative tests with 20 cm EPS and 4 mm A1 Triaxial fibre reinforced A1 resulting in B-s1,d0

The specimens meet all the criteria given in the IMO document for bulkhead, wall and ceiling products and can therefore be considered to have low flame spread in compliance with the International Convention for the Safety of Life at Sea, 1974.

A1 IMO is a water based Acrylic mineral composition and developed as a safe and environmentally friendly material for the manufacturing of panels, interior parts and other products for Cruise ships and all areas where the IMO regulations are required. This 3-component system is familiar to our other A1 systems and all existing A1 additives are compatible with A1 IMO.

A1 IMO can be used as a membrane on top of a variety of materials or to produce in-moulds. It is suitable for hand working, pouring or Spraying with a 1-component spray equipment.

A1 IMO consist of a formulated liquid, powder and a filler (A1 ATP powder), mixing ratio 1:2,25:0,25.

The Marine Equipment Directive 96/98/EC (MED covers certain equipment carried on ships registered under the flags of the European Union Member States. It was established to ensure that equipment which must comply with the requirements of International Conventions e.g. Safety of Life at Sea, 1974 (SOLAS) agreed by the International Maritime Organisation also meets common standards of safety and performance across the EU. Approval requirements are also harmonised which ensures certificates issued in one Member State are accepted by all States across the EU. Thus, all equipment listed in Annex 1 of the MED placed on EU ships, must carry a Wheel Mark showing compliance with the MED.

To ensure A1 IMO can be used on Ships we have passed the IMO Resolution MSC 307(88) (2010 FTP Code): Annex 1: Part 2 for Smoke & Toxicity and Part 5 for Surface Flammability. The tests have been done by Warringtonfire.

For the manufacturer using A1 IMO for panels or other products it’s necessary to get the Wheelmark.

Therefore Module B and Module D examination must be done.

Module B;

This is the EC Type Examination (formally Type Approval) and is the procedure by which the Notified Body ascertains and attests that a specimen of the product, representative of the envisaged production, meets the relevant provisions of the MED. The Notified Body either tests or witnesses tests and certifies (via a Type Examination Certificate) that the specimen complies with the criteria given in the Fire 2010 Fire Test Procedures Code (IMO MSC 307 (88). It is important to note that the specimens used for the tests must have been independently and randomly sampled from either stock, the market place or the production line.

Module D;

This module relates to production quality assurance and is linked therefore to ISO 9001 certification. The manufacturer must operate to an approved quality system which itself is subject to periodic surveillance. The quality system must apply to the production process, final product inspection and to quality control testing.

IMO Resolution MSC 307(88) (2010FTP Code): Annex 1: Part 5

Test for Surface Flammability

ENGLISH VERSION

IMO Resolution MSC 307(88) (2010FTP Code): Annex 1: Part 2

Smoke & Toxicity

ENGLISH VERSION

EC-TYPE EXAMINATION

CERTIFICATE

Module B

ENGLISH VERSION

QS – CERTIFICATE OF

ASSESSMENT – EC

Module D

ENGLISH VERSION