Cladding & Theming

A1 Cladding

A1 the waterbased composite

Since the beginning of this new millennium A1 (Acrylic One) material has been successfully applied world-wide in various Cladding products and applications.

Besides the well-known benefits of composites (freedom of shape, light weight and strong), A1 has a superior fire resistance and absence of smoke generation during fire.

The components are a powder component based on calcium sulphate (CaSO4) and an acrylate-based liquid. After mixing off these components the resin can be processed to make products.

The resin is water-based and does not generate the emission of VOC’s (Volatile Organic Solvents). Additional filler (e.g. sand) can be added to the mixture as well.

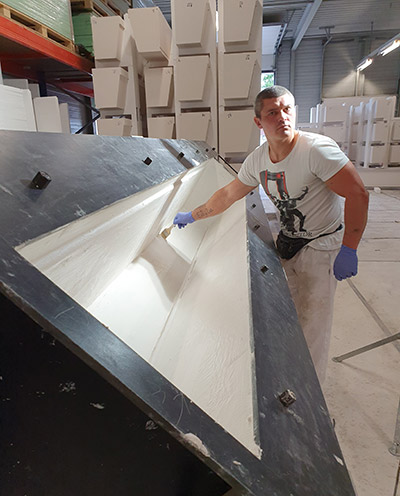

Specially in combination with a glass fibre reinforcement, thin-walled products can be made with a complex shape and with a low weight.

Because of the short curing time, short production times are possible. This enables an efficient production process.

A1 gives freedom of design

A1 has excellent fire ratings

A1 claddings are lightweight

imitation

When you need (for example) a brick, a concrete, a natural stone or a wooden expression, but the original material is not available or possible anymore, then consider using A1.

A1 will make perfect copies by using a silicone mould. Use fillers and pigments to get the desired expression.

renovation

Give your existing building a complete new feel and look. Because of the freedom of shape, expressions and lightweight properties A1 is the ideal material to upgrade your building with a complete new façade.

Often the the existing background support structure will be suited for the attachment of your complete new A1 façade.

innovation

Create unique designs as A1 gives you the freedom of a composite material.

Combine this with your own mixture of fillers and pigments to develop your own feel & look. The result will be designs that are impossible to realise in other materials but more important are a reflection of your imagination.

freedom of expression

You need to duplicate an existing structure, but the original material is not suited or not available anymore. You need concrete feel and look without the weight of concrete. You need the feel and look off wood but with high fire resistant properties. You need a huge brick wall but the support structure is not strong enough for real bricks. You need a natural stone feel and look but real natural stone is too expensive.

In all these cases A1 might be your answer.

A1 Theming

projects and applications

Since the beginning of this new millennium A1 (Acrylic One) material has been successfully applied world-wide in various Theming projects and applications.

Besides the well-known benefits of composites (freedom of shape, light weight and strong), A1 has a superior fire resistance and absence of smoke generation during fire.

The components are a powder component based on calcium sulphate (CaSO4) and an acrylate-based liquid. After mixing of these components the resin can be processed to make products.

The resin is water-based and does not generate the emission of VOC’s (Volatile Organic Solvents). Additional filler (e.g. sand) can be added to the mixture as well.

Specially in combination with a glass fibre reinforcement, thin-walled products can be made with a complex shape and with a low weight.

Because of the short curing time, short production times are possible. This enables an efficient production process.

Glass Fiber Reinforced A1 (Acrylic One)

Glass Fiber Reinforced A1 (Acrylic One) is often used as a replacement for Glass Fiber Reinforced Polyester and even for Glass Fiber Reinforced Concrete both internally and externally.

A1 has excellent fire resistance properties and can be used for projects with high fire resistance requirements.

A1 can overcome many of the problems associated with GRP, a material that is becoming less favoured by specifiers because of its inherent toxic fume and dense smoke emissions in fire and its poor performance after long exposure to ultraviolet.

In comparison with GRC, A1 offers much greater versatility as a panelized theming system in that the manufacturing tolerance can be much tighter and in situation where the weight per m² is critical.

A1 Theming projects

A1 is world wide available. Next to our extensive distribution network in Europe we have partnerships in South Africa, China, Malaysia, Australia and Russia (via Latvia). A1 for the Middle East is represented by our distributors in Dubai and The Kingdom of Saudi Arabia. If no partner or distributor is nearby we ship A1 World Wide via the port of Rotterdam, which is only 20 km from our Headquarter.

Visit the overview of partners and distributors at www.activecomposite.com